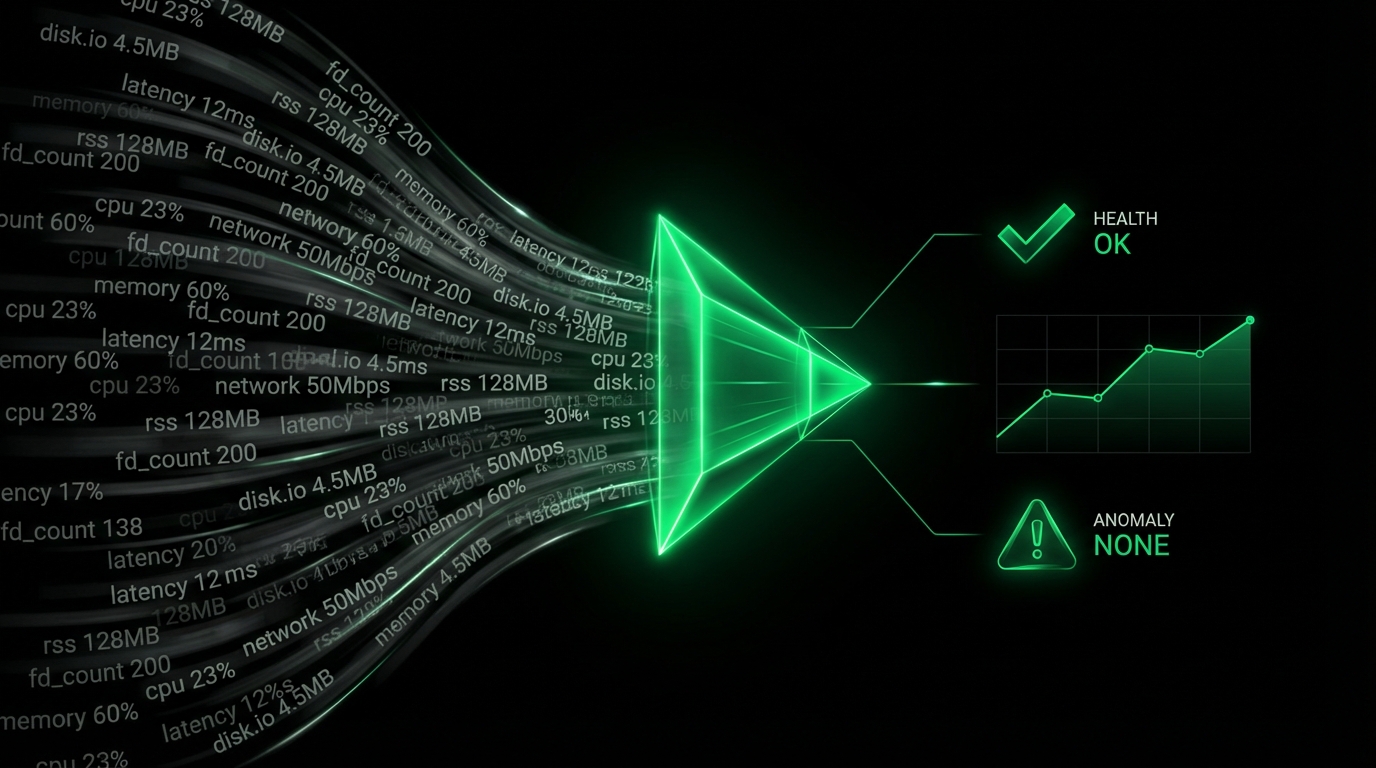

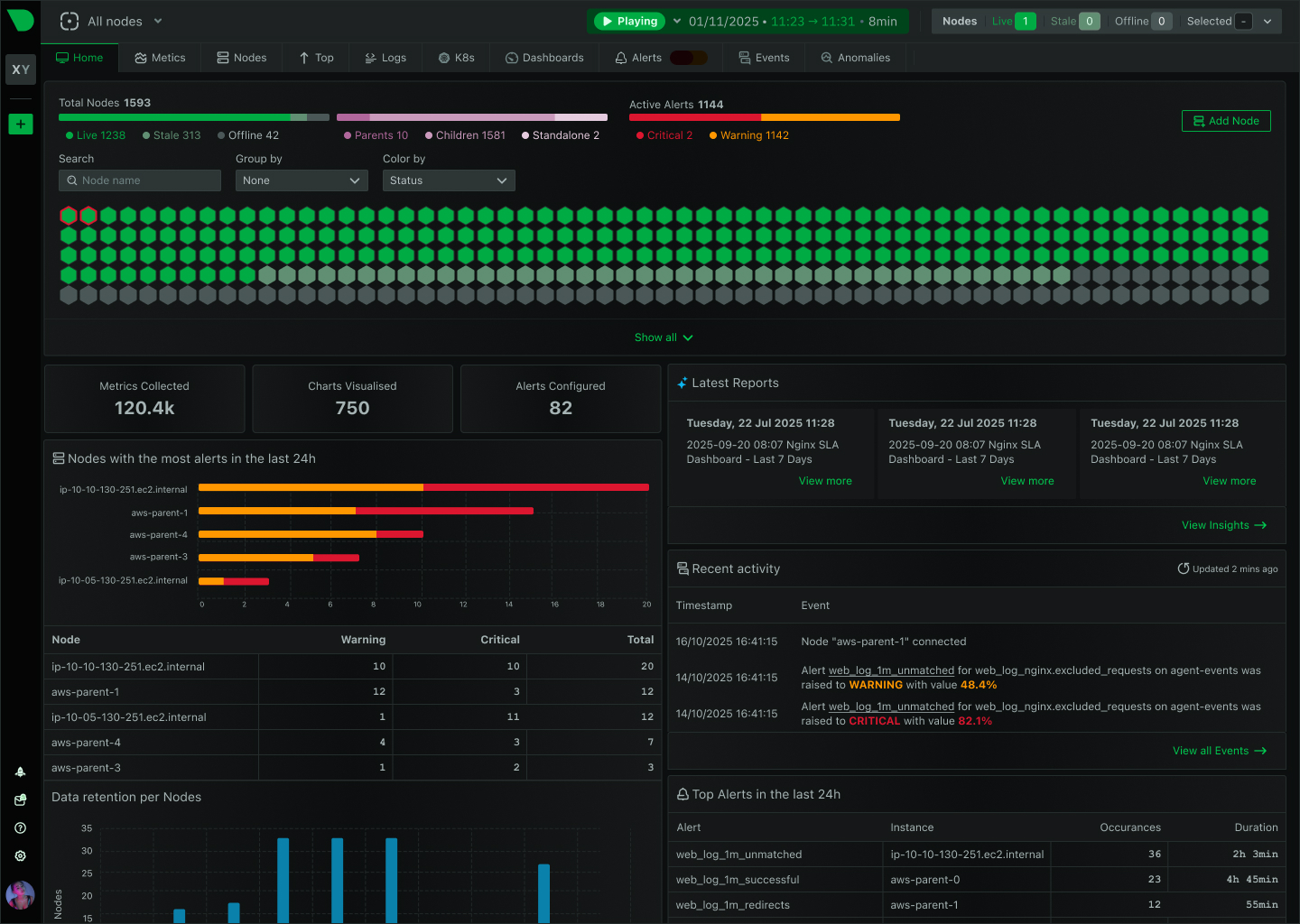

See Every Production Second. Fix Issues in Minutes.

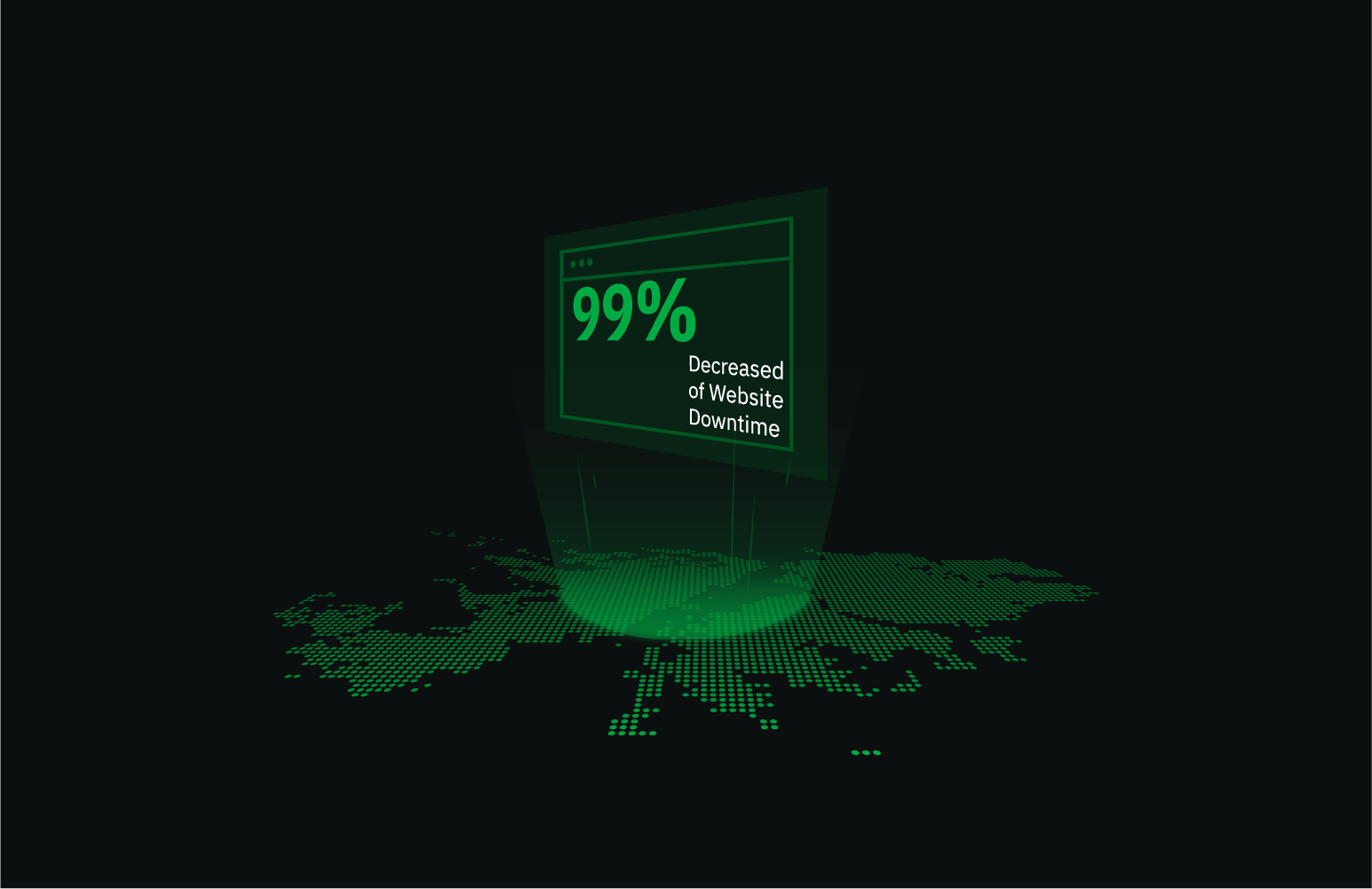

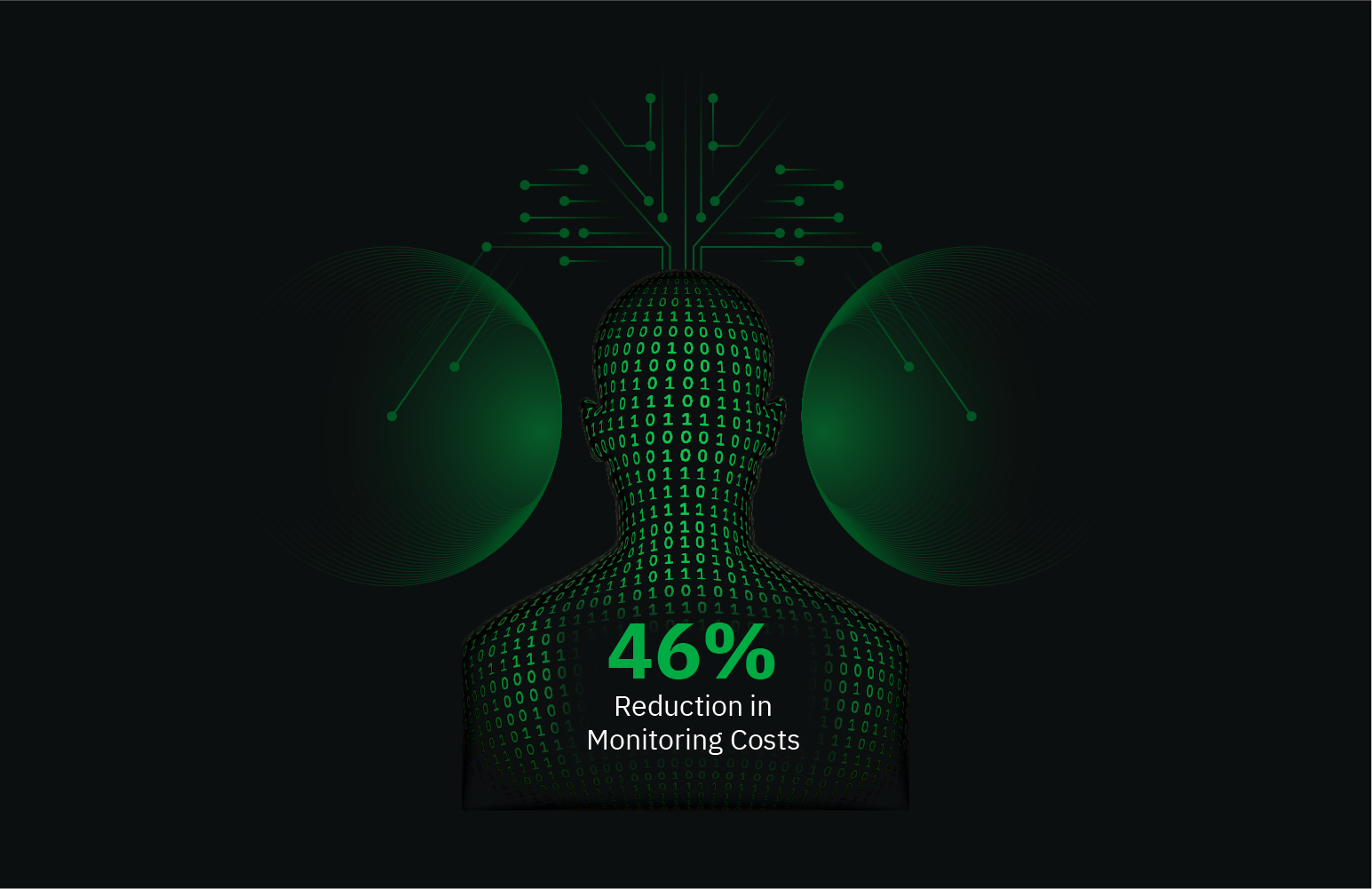

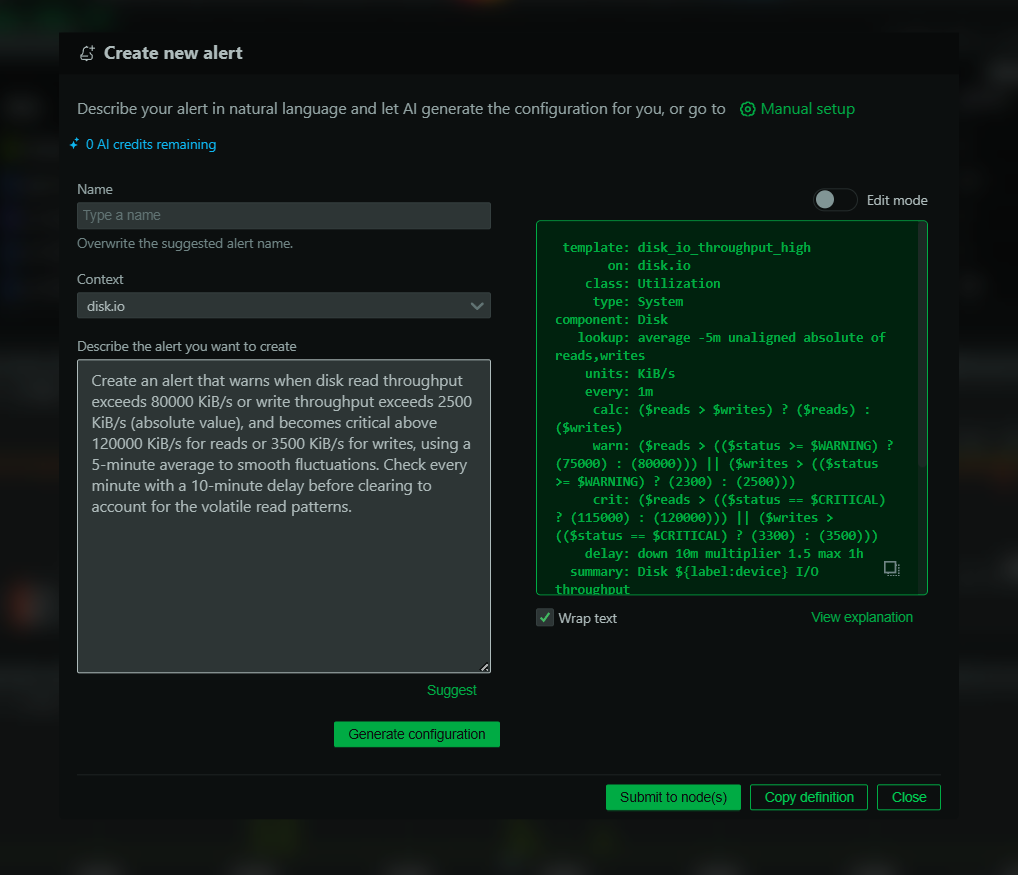

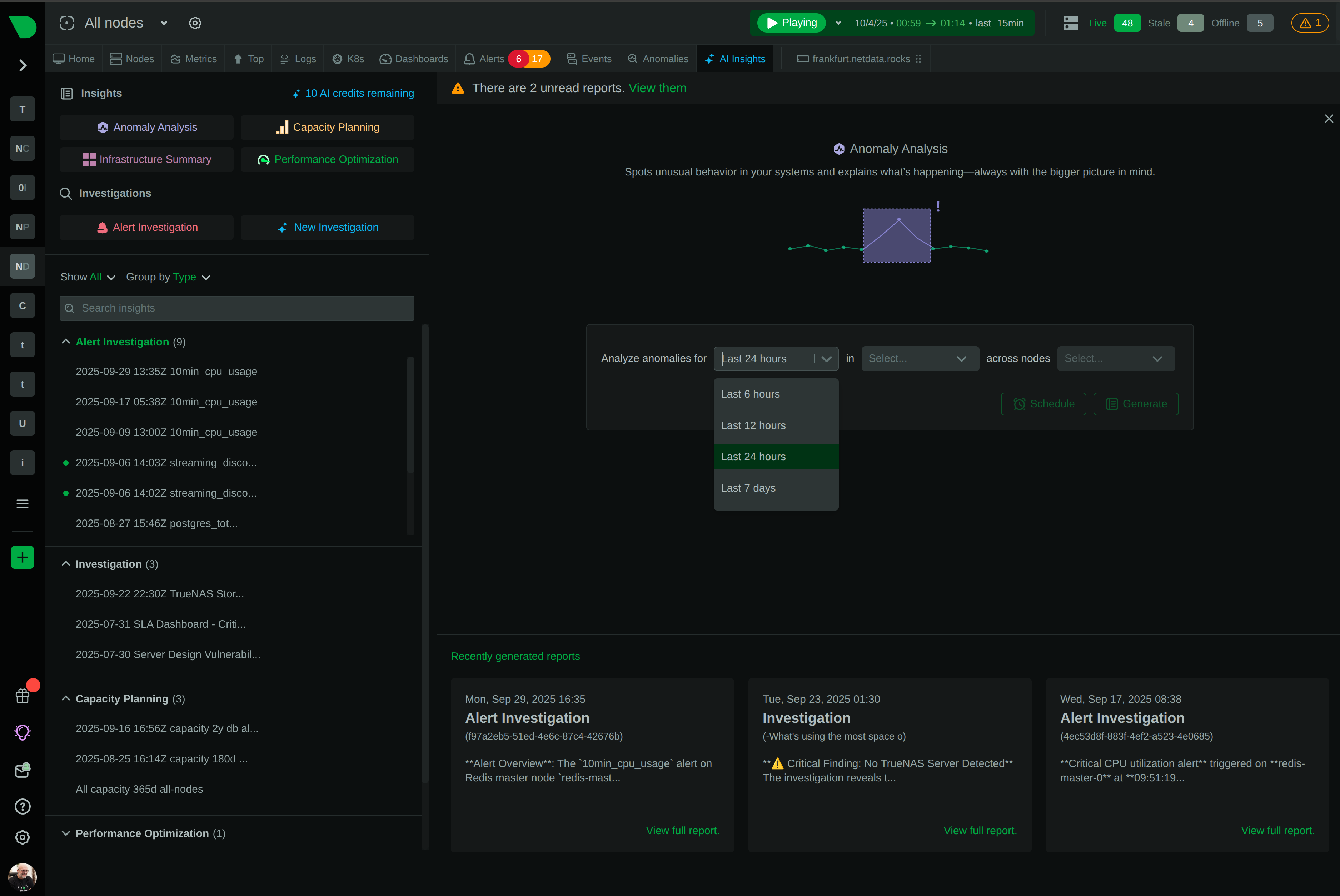

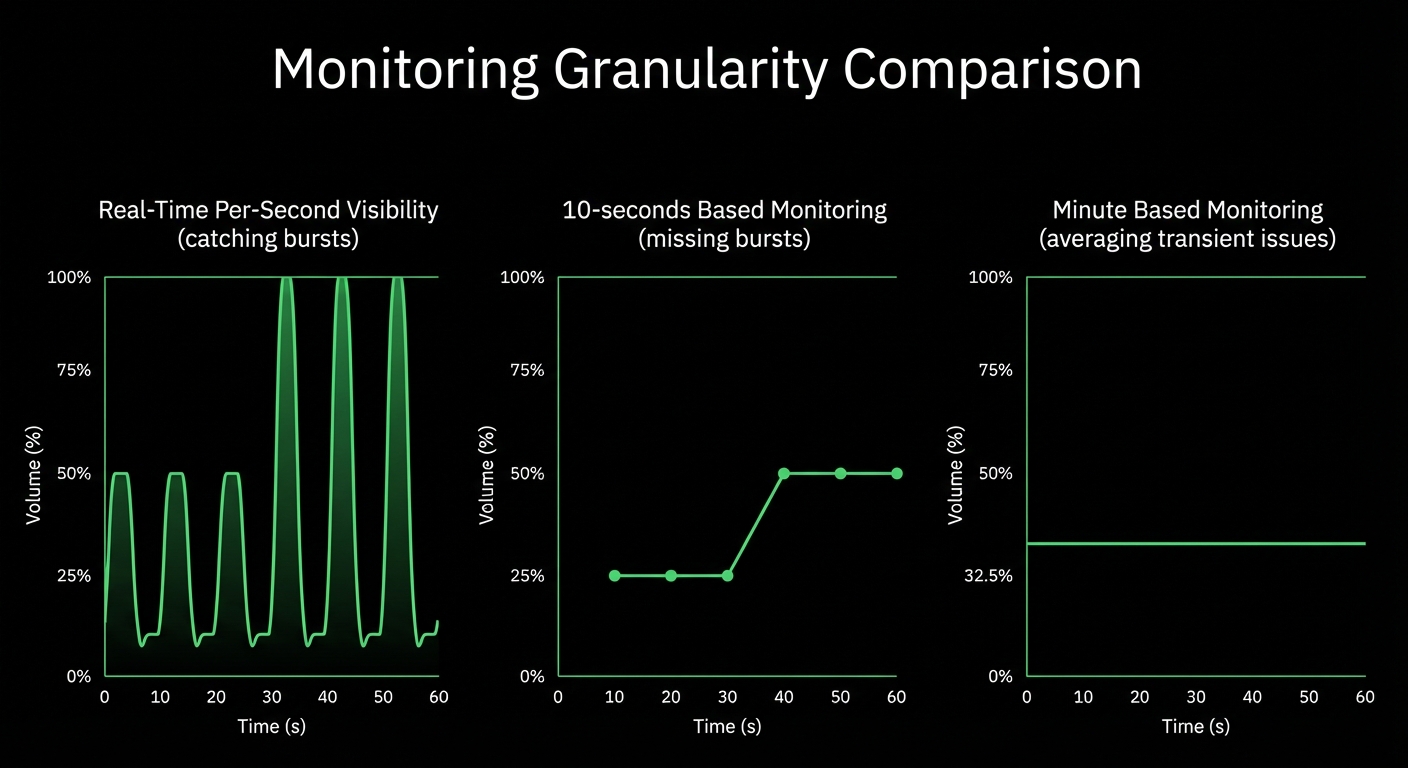

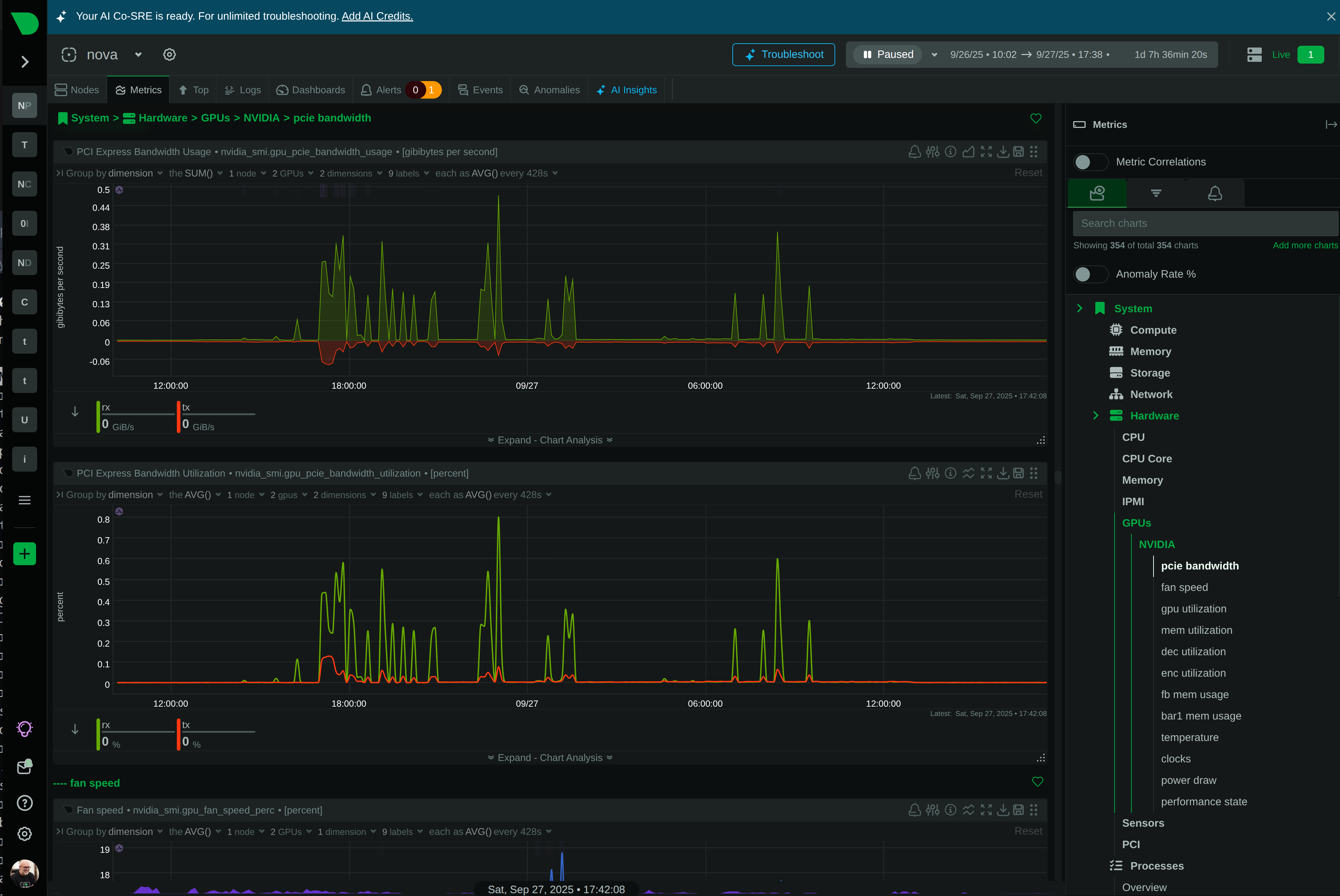

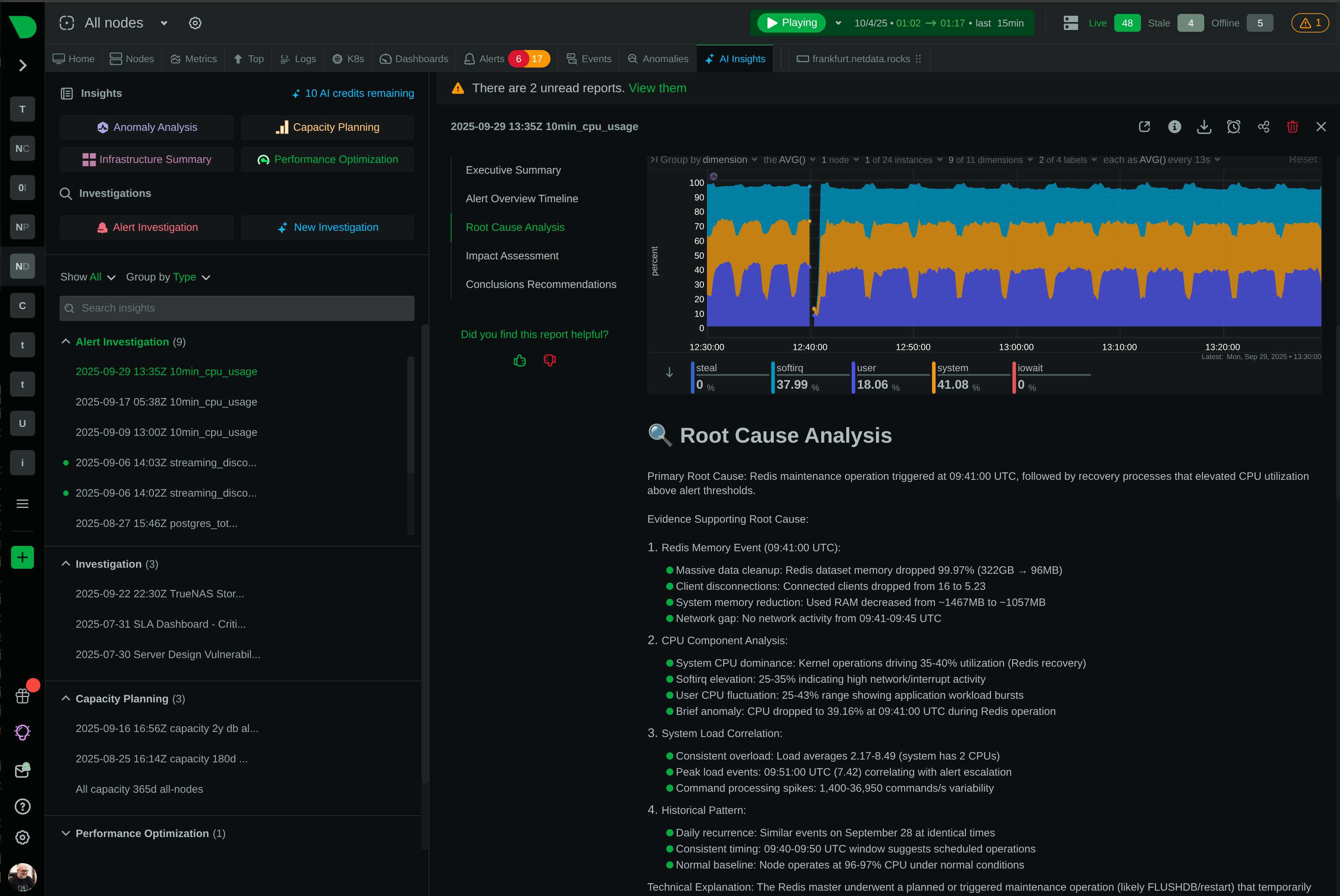

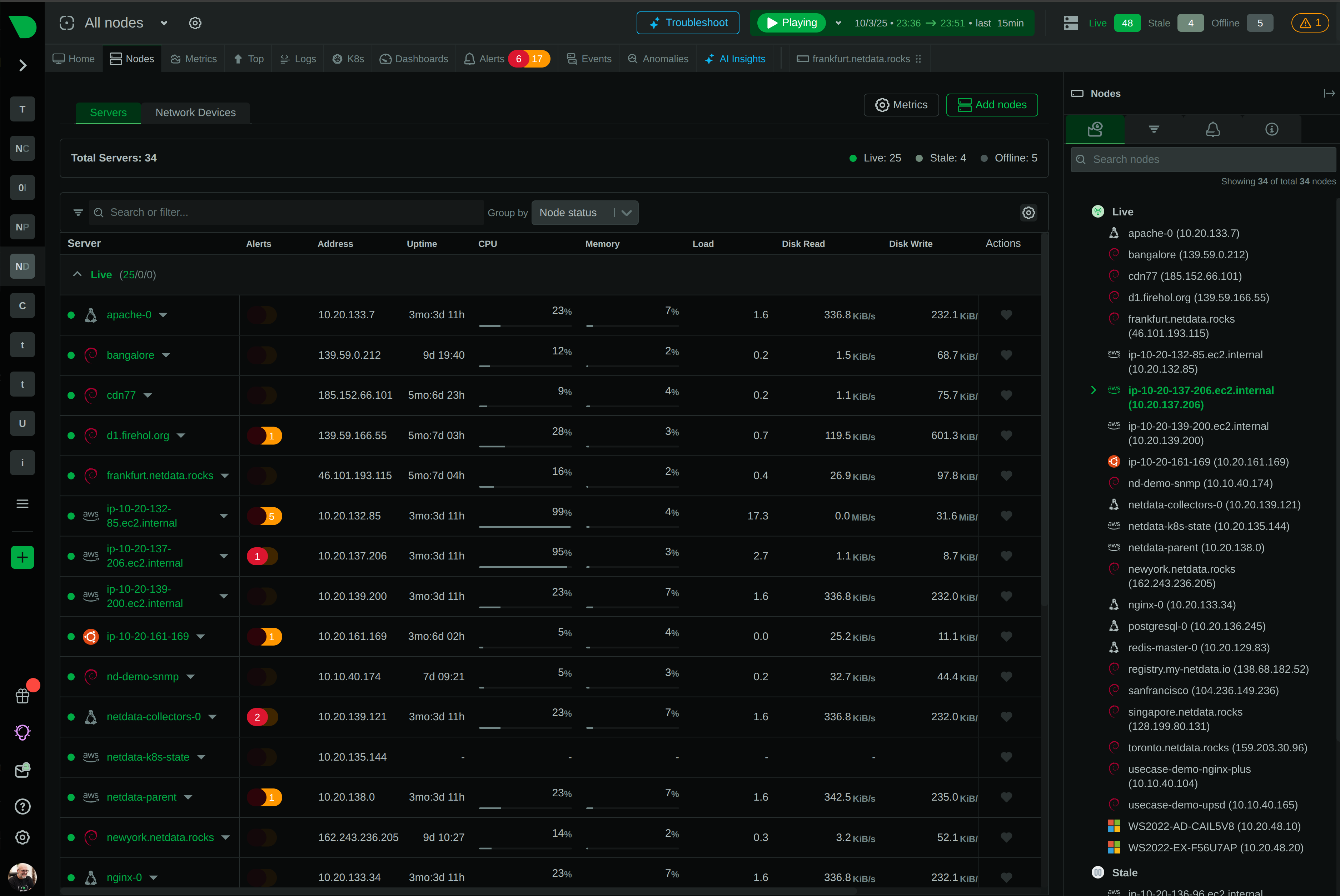

Manufacturing moves at machine speed - your monitoring should too. Netdata delivers per-second visibility across production lines, SCADA systems, and industrial infrastructure with ML-powered anomaly detection that catches problems before they cascade into costly downtime.